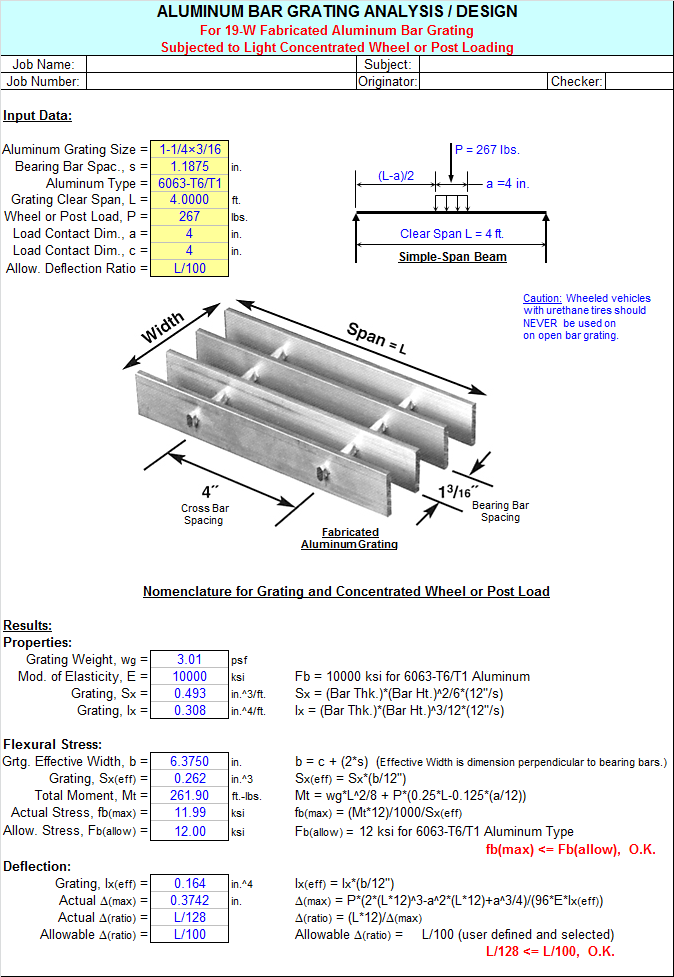

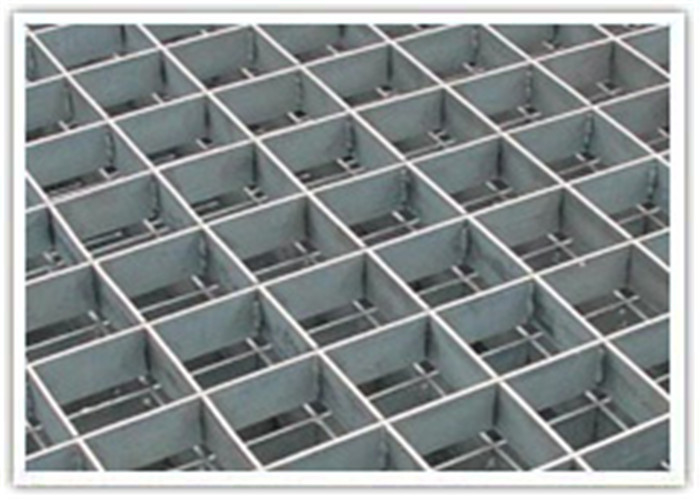

Theload bearing capabilities and deflections of grating are based on the structural properties of the bearing bars and the number of bearing bars supporting the load.

Metal bar grating manual.

The information contained is based on sound engineering principles and reflects practices recommended by leading manufacturers in the industry.

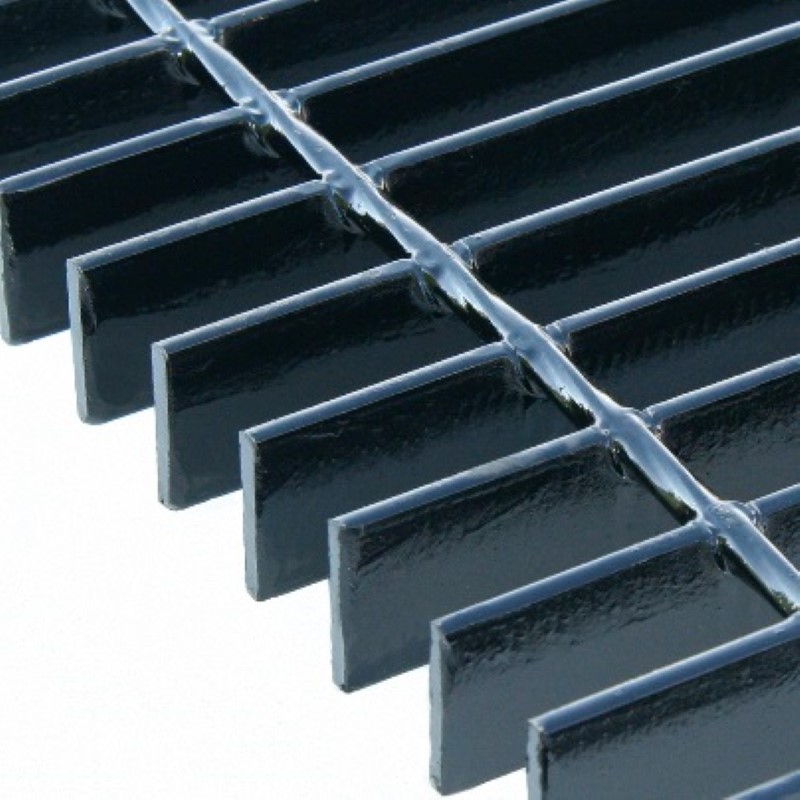

Gratings and frames shall be hot dip galvanized per astm a123 or powder coat painted black as shown on the drawings.

Metal bar grating this manual sets forth procedures used in design calculations for metal bar grating.

21 2 63 5 mm maximum bearing bar thickness.

Provide appropriate fasteners for type grade and class required for the approved anchorage system.

The naammmetal bar grating manual provides architects and engineers with current technical data on bar gratings and stair treads of steel stainless steel and aluminum.

Metal bar grating manual 531 17.

Essential current technical data concerning heavy duty bar gratings of structural carbon steel and stainless steel.

Includes photographs load tables and details of typical installations.

The information contained is based on sound engineering principles and reflects practices recommended by leading manufacturers in the industry.

Ansi naamm mbg 531 17 download pdf.

0 each technical data specifications and recommended practices applicable to steel stainless steel and aluminum gratings.

Includes information on types of gratings fabrication dimensional standards load tables installation and guide specifications.

The naamm metal bar grating manual provides architects and engineers with current technical data on bar gratings and stair treads of steel stainless steel and aluminum.

532 09 metal bar grating manual.

The naamm metal bar grating manual provides architects and engineers with current technical data on bar gratings and stair treads of steel stainless steel and aluminum.

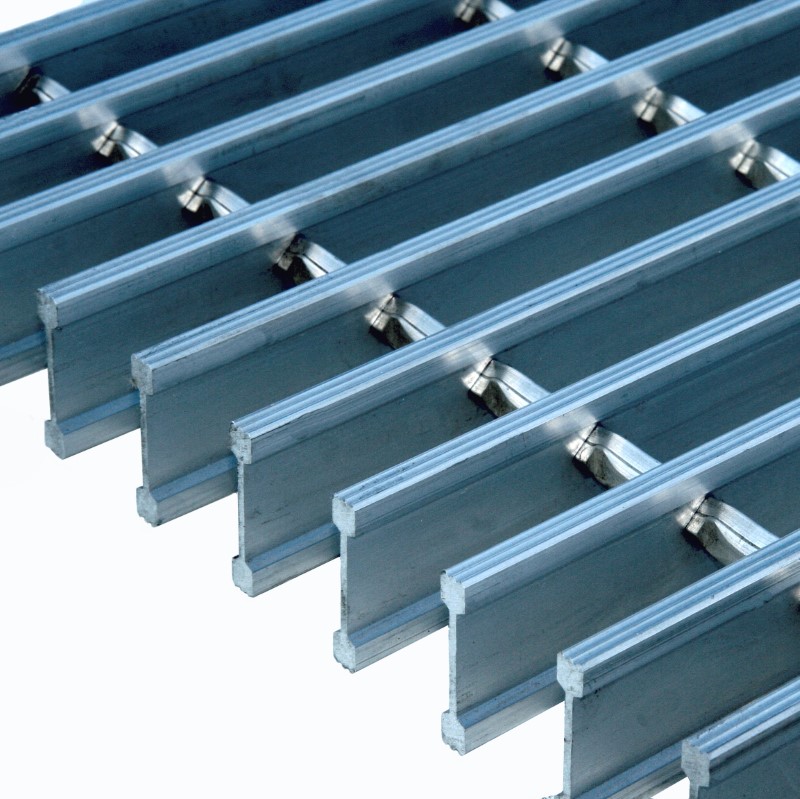

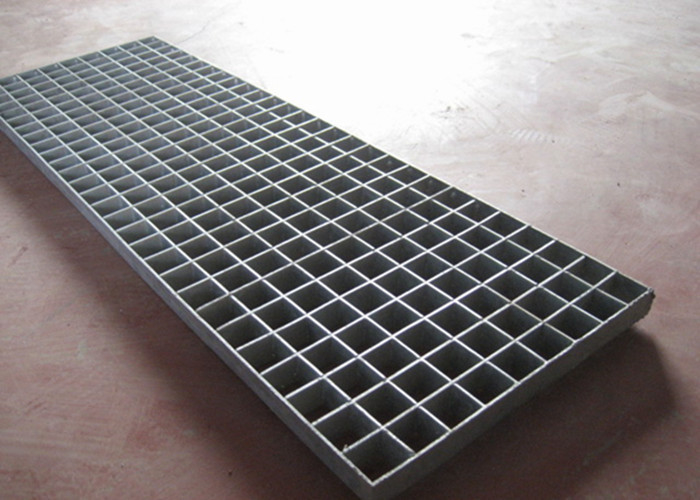

It regularly appears on catwalks factory floors platforms railing infill panels and as stair treads.

Mbg 531 00 american national standard ansi naamm metal bar grating manual sixth edition maximum bearing bar depth.

A series of bearing bars are welded swage locked or press locked together with perpendicular crossbars to form the panels.

Include lifting devices as shown on the drawings.

The information contained is based on sound engineering principles and reflects practices recommended by leading manufacturers in the industry.

Mcnichols bar grating brings safety strength durability and character when installed in either industrial or architectural applications.